PET kub npog daim kab xev

Yam ntxwv

Qhov zoo ntawm cov kua nplaum tshwj xeeb silicone rau cov tsiaj kub kub daim kab xev:

Nws muaj qhov kub thiab txias tsis kam, siab adhesion, tsis muaj nplaum residue tom qab tev thiab hnyav ua haujlwm.

1. Zoo heev pib adhesion thiab adhesion;

2. Tsis muaj kua nplaum residue, tsis muaj warping, tsis poob tawm tom qab ci

3. Solvent resistance, acid thiab alkali tsis kam

Lub hom phiaj

① Tsiaj kub daim kab xev yog tsim rau kev kho mob saum npoo hlau xws li lub computer chassis thiab cov khoom, cov hmoov kub kub tsis txau, thiab cov xim ci yog siv los tiv thaiv kev tiv thaiv;

②pet kub daim kab xev kuj tseem tsim nyog rau kev tiv thaiv kev tiv thaiv thiab rwb thaiv tsev thaum kub txau ntawm cov khoom siv hluav taws xob, kev lag luam tsheb, txheej thiab lwm yam khoom;

③ Nws yog siv los kho cov ntawv luam tawm Circuit Board, cov khoom siv hluav taws xob, cov khoom siv hluav taws xob thiab cov khoom siv hluav taws xob thaum lub sij hawm tsim khoom thiab tiv thaiv cov ntiv tes kub thaum lub sij hawm impregnation txheej txheem ntawm PCB board thiab tiv thaiv lub immersion thiab kuab paug ntawm electroplating kua, thiab rau kev tiv thaiv ntawm luam ntawv. Circuit Board los ntawm kub plating;

④ Cov cuab yeej siv hauv tsev, tshuab, khoom siv hluav taws xob thiab lwm yam lag luam xav tau kev pleev xim kub thiab txau tiv thaiv, thiab cov tsiaj ntawv kub kub ua lub luag haujlwm ntawm qhov kub thiab txias khi thiab kho.

⑤ Lwm daim ntawv thov: cov tsiaj ntawv kub kub kuj tuaj yeem siv rau hauv cov ntawv tso tawm cov pob qij txha

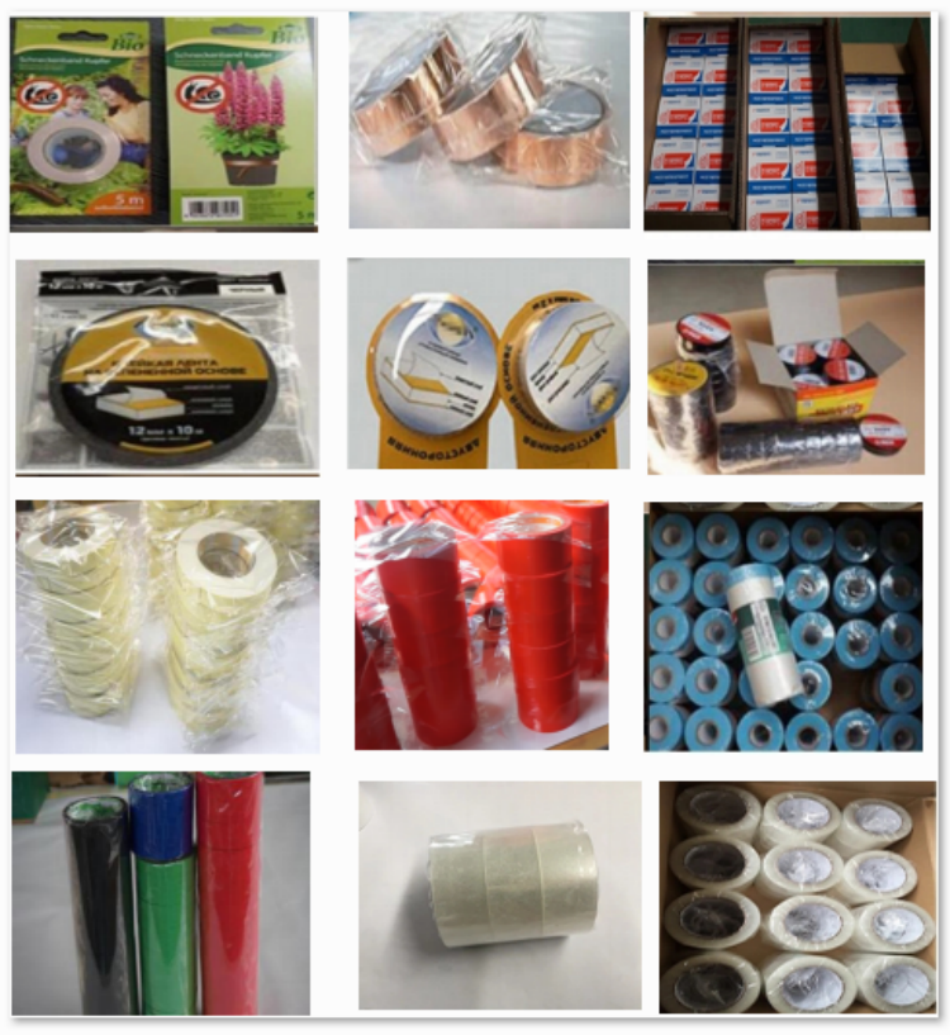

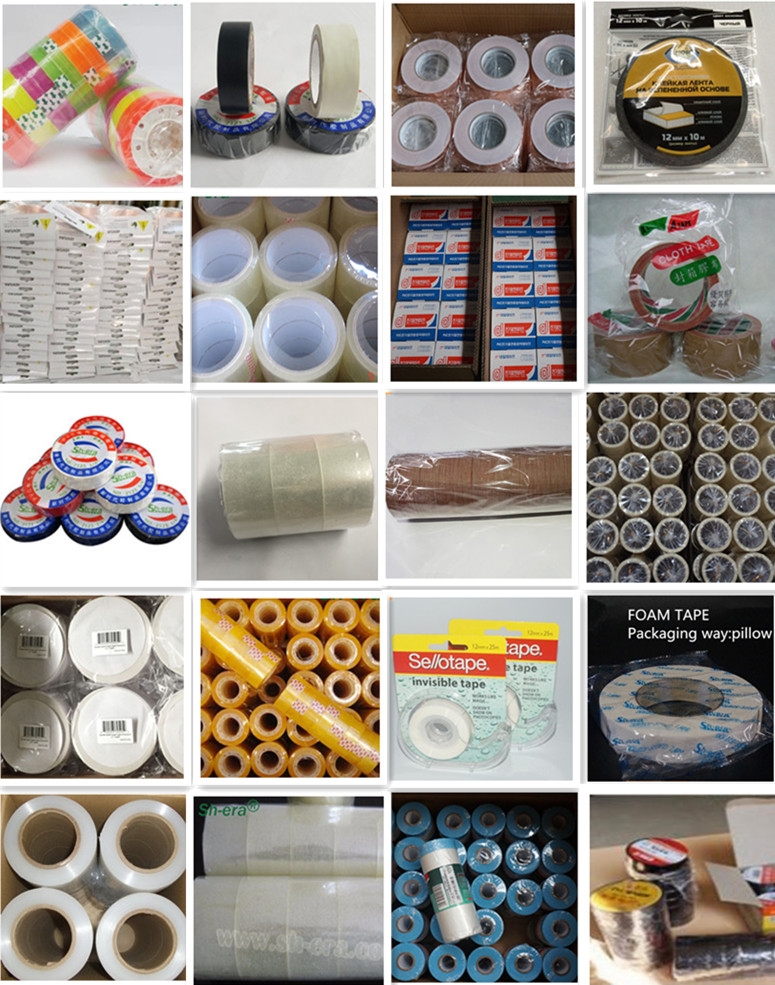

Cov khoom pom zoo

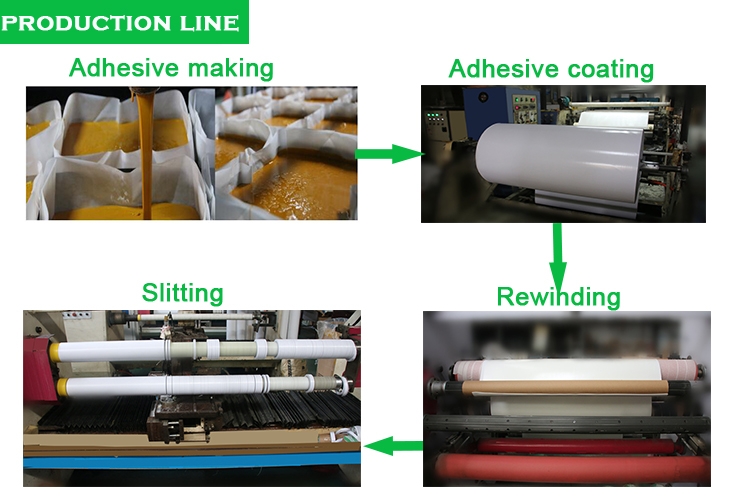

Ntim Cov Lus Qhia