Muab ob npaug rau-sided hloov daim kab xev tsis muaj cov ntaub ntawv thaub qab

Yam ntxwv

1. Pob tshab ntshiab zaj duab xis daim kab xev

2. Zoo pib viscosity thiab nruam viscosity

3. High cohesion, zoo plasticization kuj thiab zoo heev tuag-txiav kev ua tau zoo

4. Tsis muaj kua nplaum residue, overflow kua nplaum, tshuaj stability, tsis kam mus organic solvents, tshuaj tua kab mob, roj, tsis muaj zog acids, ntsev yaig.

5. tuaj yeem siv rau ntau qhov chaw hnyav rau lub sijhawm ntev

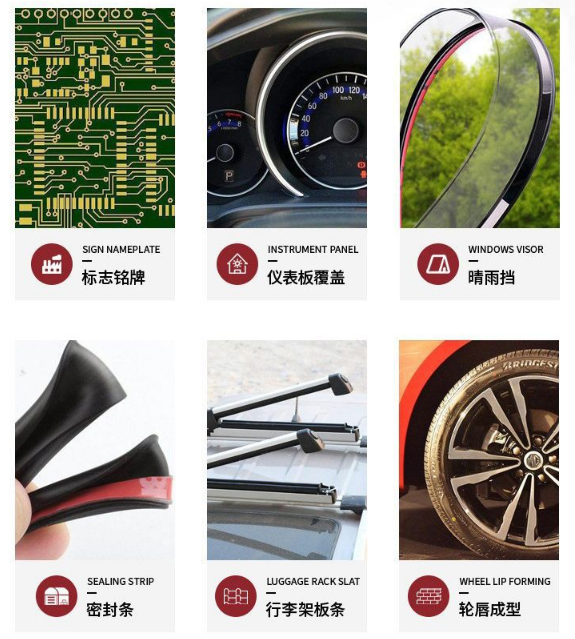

Lub hom phiaj

1. Cov ntawv sau npe, cov ntawv cim, cov cim: siv rau hauv kev tshuaj ntsuam luam ntawv, kev tshaj tawm, aviation, khoom siv kho mob thiab kev lag luam, tsheb, khoom siv hauv tsev, kev lag luam hluav taws xob thiab lwm yam lag luam.

2. Soft board FPC: siv rau hauv xov tooj ntawm tes, phau computers, PDAs, digital koob yees duab, LCM thiab lwm yam khoom siv hluav taws xob

3. Membrane hloov: Membrane hloov nrog saj zawg zog, nruj, concave thiab convex pawg

4. Shockproof ua npuas ncauj: zoo pib viscosity thiab stickiness, siab cohesion, thiab zoo plasticization kuj.

Lub hom phiaj

Qhov kub thiab txias npog daim kab xev yog dav siv nyob rau hauv qhov chaw txau daim npog qhov ncauj, nruab nrab-siab kub npog daim kab xev dav siv nyob rau hauv lub npog qhov ncauj ntawm industrial nto txau, kub resistant masking daim kab xev yog siv nyob rau hauv tsheb thiab rooj tog thiab txheej txheem txheej, PCB board tsau drilling;

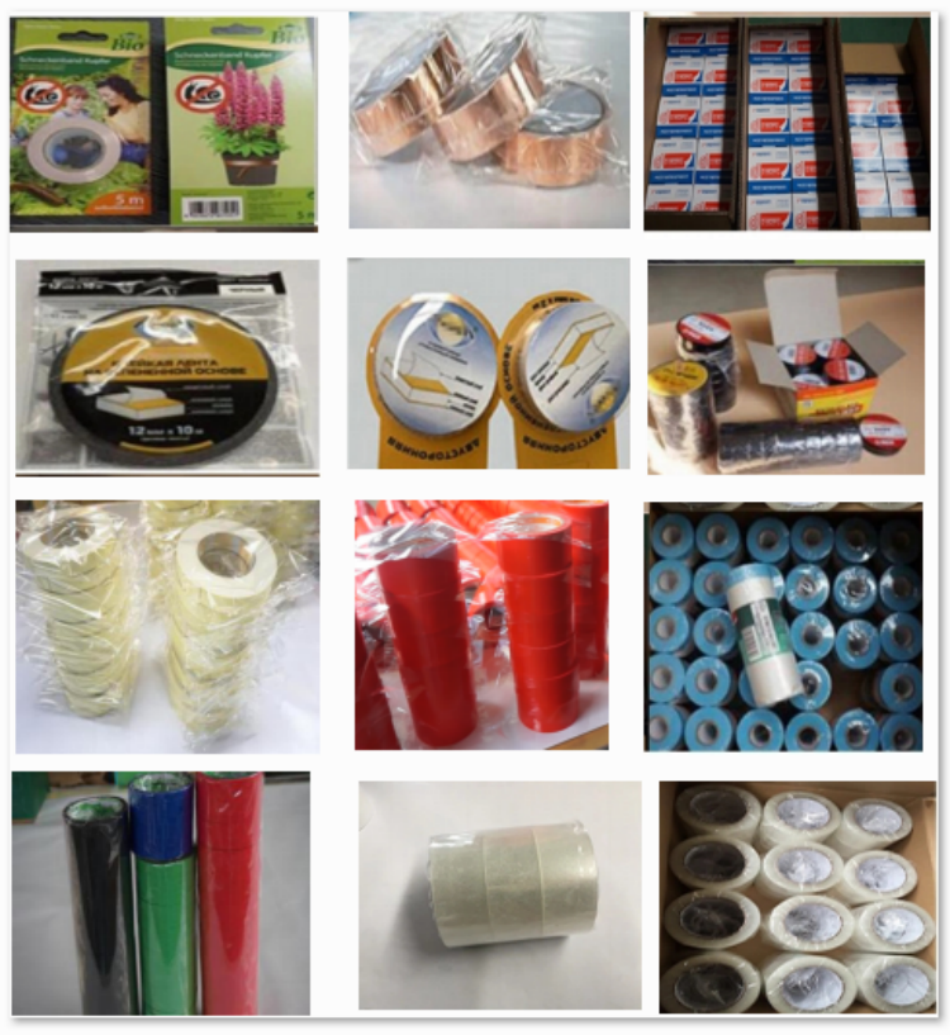

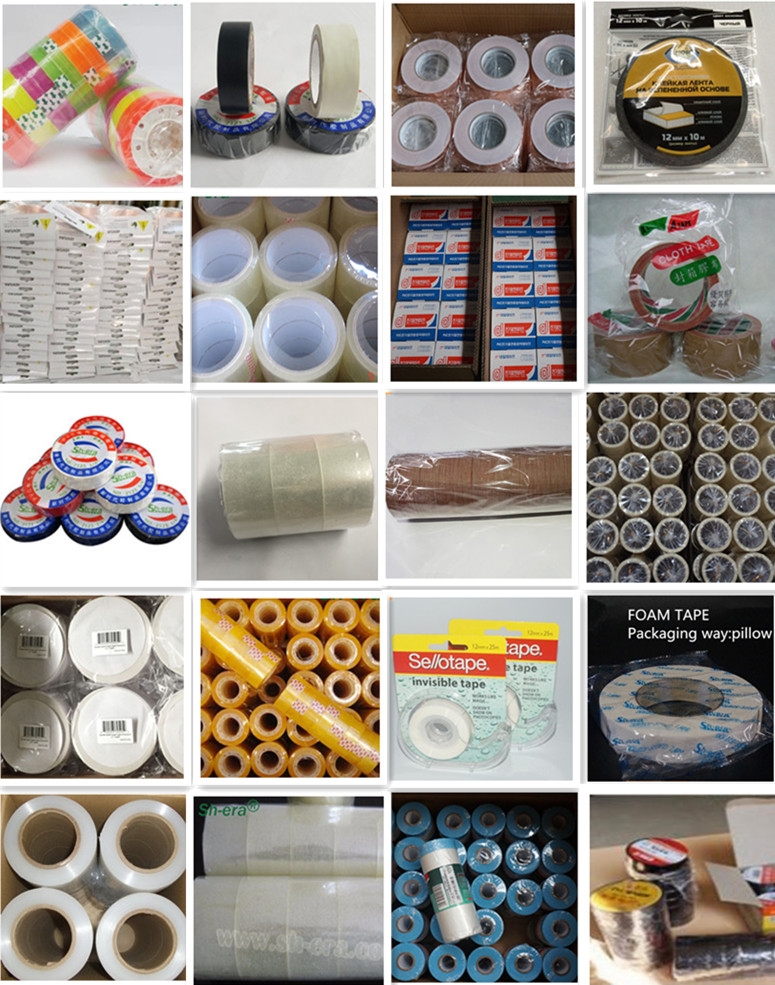

Cov khoom pom zoo

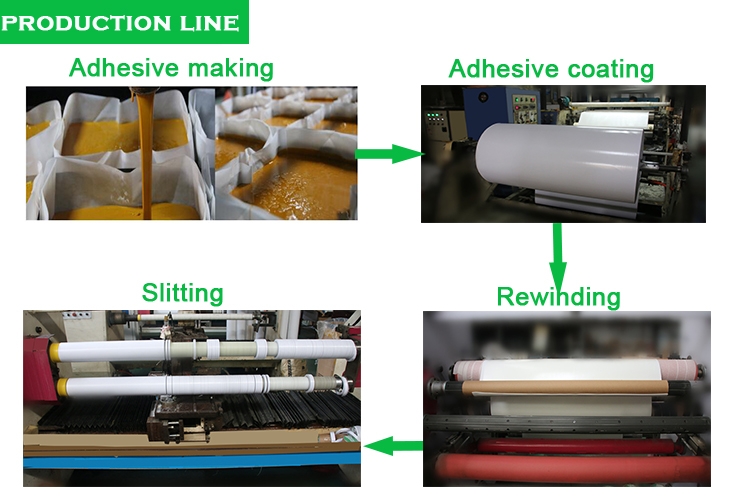

Ntim Cov Lus Qhia